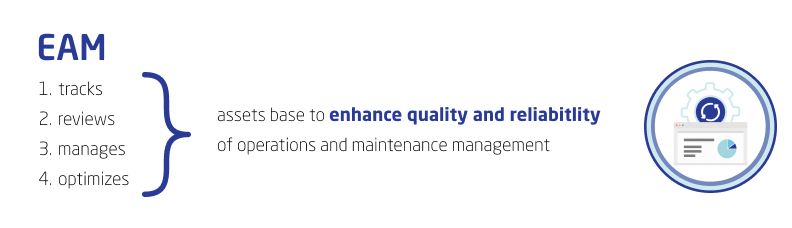

Modern and high-performing organizations demand customized and effective software to manage their business-critical assets. It is the assets that deliver true value, and those same demanding organizations strive for asset management excellence. In doing so, they use EAM to track, review, manage, and optimize their critical asset base. Like many other industries that use EAM, manufacturers utilize it to enhance the quality and reliability of operations and maintenance management.

The Evolving Role of EAM

EAM tools and processes are constantly expanding and evolving. Gone are the days of paper and pencil.

Beyond the array of features, modern enterprise asset management systems offer great benefits. EAM will streamline operations, maximize asset utilization, centralize asset hierarchy data and information, and greatly improve maintenance and work management over the entire asset life cycle.

More and more companies are adopting and using EAM for asset management and optimization of their physical assets over the full life cycle from procurement to disposal. This constant innovation of EAM tools gives organizations a competitive advantage in balancing the three variables of asset management: cost, risk, and performance.

EAM: How it Makes a Difference

Gartner's research shows that technology advances like artificial intelligence (AI), the Internet of Things (IoT), and virtual reality (VR) are changing traditional asset management and maintenance practices forever. Engineers can now stream live asset data from sensor arrays to their mobile devices. Failing assets alert their owners by text or email. Original equipment manufacturers (OEM) ‘dial in’ by VR to help engineers repair assets in the middle of the night.

At its core, it's business intelligence. And the world has changed.

Asset-intensive organizations and enterprises now understand the relevance of modern-day EAM and the difference it makes. All stakeholders should understand. That said, the burden of final responsibility lies with Chief Information Officers (CIO) to plan and roll out EAM systems that can improve operational capability, equipment maintenance and asset management standards.

Latest EAM Trends

There are several new trends in asset management - together with new features for EAM software - that can boost organizational resilience and output in 2022.

Cloud-based Software Solutions

The preference for and prevalence of server-based software is slowly giving way to cloud-based software platforms and software as a service (SaaS) subscriptions. In tandem with these changes, overall costs are coming down and implementation times are reducing for the majority of businesses. No longer is an EAM system the preserve of global corporations and large enterprises only. Nowadays, these systems are well within the reach of small and medium businesses – primarily because of lowered costs compared to traditional systems, and secondly because of ease of accessibility and implementation.

Digital Inspections and Sign Offs

The reliance on paper is decreasing rapidly. Modern EAM systems now allow users to perform digital inspections and digital sign-offs. Once an organization moves its paper inspections and work orders into cloud-based EAM software, it makes document compliance accessible, searchable, and reportable for analysis and audits. And backups can be created securely at a single keystroke.

Mobile Device Capabilities

Mobile devices are all around us. There are apps for almost everything and EAM platforms are no different. For your EAM to boost your productivity, it must have mobile capabilities. The integration of mobile devices and tools across your enterprise will create a fully connected ecosystem streaming rivers of data back and forth in real time. This connectivity enables rapid communication, and your team can do more in less time.

Case Study- Storage and Warehousing Industry

According to a Research and Markets report, the industry is expecting a compound annual growth of 10% between 2020 and 2025. To respond to this demand, the industry is employing EAM technology for support. Itis realizing increased production time by streamlining its preventive and corrective maintenance. This will lead to higher availability, output, and profitability.The industry is also embracing digital inspections for maintenance and complying with regulations. Mobile EAM has become a time-saving device for fleet and asset inspections.

The Future of Asset Management

The future of asset management is bright. Big data, 3D printing, edge computing, increasing business value, and supply chain optimization will drive the need for more features and capabilities in the coming years.

In time, enterprises will be able to collect, share, and monetize data along with intellectual property (IP) rights for their assets and production facilities. At the same time, enterprises will also need to put in place privacy protections and secure their IP rights.

What Should be the Approach in the Manufacturing Industry?

Firstly, decide whether you need to update or replace your current EAM system. For the demands of manufacturing, it is highly advisable that businesses first modernize any older or legacy EAM systems that don’t provide digital mobility or cloud-based options. And also consider an ERP or EAM vendor that provides scalable EAM functionality.

Then make that long-term commitment.

Manufacturers should proactively invest in a dedicated platform to expand their operations and asset and maintenance management capabilities. These enterprises need to engage with their suppliers and service organizations to take a closer look at their technical expertise and where they can add value to the EAM system.

Data protection is critical.

For the same suppliers and service organizations with whom the manufacturer exchanges data, it is inadequate to only know what asset-specific data they are using. In fact, the manufacturer must understand and implement changes to make to ensure a high degree of data protection on the EAM platform. A better approach would be to opt for an information and service-based value network. But the enterprise may first have to wait until it can combine and transform the value of its traditional assets.

The good news is that EAM systems have become highly advanced software products and can support data-intensive operations. Although it depends on the operational complexity, the approach should not be to jump back and forth to different vendors. Manufacturers should opt for a vendor that can help minimize the overall complexity and cost of integration.

What about cloud deployment?

The growing global use of the cloud has paved the way for further growth of EAM platforms and vendors.

Cloud deployment eliminates the need for upfront software and hardware requirements, reducing the complexity and costs of managing an IT infrastructure. A study shows that almost 9 out of 10 cloud users reported cost savings. At the same time, more than half of them agreed that cloud services boost profits.

Some manufacturing enterprises are somewhat resistant to change from server-based, locally-hosted software to the cloud option. Many EAM vendors indicate that demand for the cloud option is not accelerating as rapidly as expected, but most market insights indicate that cloud-based EAM is on the right track.

Those excellence-focused manufacturers who are ready to embrace the cloud option for asset management are those who will reap the rewards sooner.

EAM Uses in the Manufacturing Sector

For manufacturing businesses and enterprises, there are several key areas where an EAM system will deliver value for its asset base and operations.

- Flexible Deployment and Integration

Modern manufacturers want flexibility of deployment, and scalable and mobile solutions. This means tablets, smartphones, PCs, laptops, and cloud-based software. And flexible pricing plans. Not everyone wants or needs a premium product, mostly because of the size of the organization or maintenance maturity and complexity.

2. Asset Hierarchy

Your asset hierarchy or directory will give your organization a solid foundation for asset criticality, life data, asset categories, condition, and locations.

- Work Order Management

Professional work management will allow maintenance engineers to report work order status and progress in real-time, consume spare parts, and quickly and efficiently complete work orders on a mobile device.

- Cost Tracking and Control

Understand costs from a whole plant level down to asset component level (e.g. a bearing on a conveyor) or the combined cost of an asset and all its sub-assets (a production robot and all its servo drives). With this cost data, valuable business insights will follow.

- Resource Planning and Allocation

Technicians' and engineers' times have to be planned out and used effectively and efficiently to achieve asset management goals. The best EAMs facilitate this function easily.

Most often it is asset-intensive larger enterprises that better utilize EAM software. This is because big companies need performance data and information to operate and manage physical assets on multiple locations and sites simultaneously.

General Motors

The renowned manufacturer uses and EAM and RFID tracking tools to monitor its assets and collect and store accurate performance-based data. With RFID tracking, GM has managed to build a comprehensive data repository on asset location, condition, and potential life expectancy that helps data-driven decision-making during the asset life cycle.

Final thought

The quest to maximize business value is never-ending, but this will allow enterprises to monetize data every time a product or service is rendered, sold, delivered, and consumed. In 2022, it makes perfect sense for modern, agile organizations to adapt organizational goals to suit these changing times and changing sources of value.

At the same time, it is crucial for asset-intensive enterprises to choose the most suitable EAM vendor to make strategic and data-driven decisions on the asset management journey. Whether it is realized or not, enterprises that want to remain competitive cannot successfully manage physical assets without an EAM system in place.