Create and plan preventive & corrective maintenance

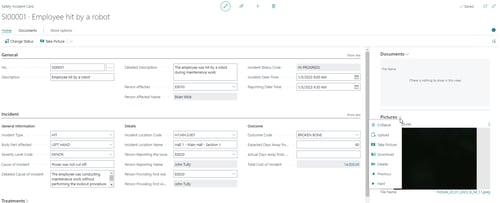

- Quickly react with corrective maintenance to incidents or requests – also from our Power Apps

- Effectively manage your preventive maintenance schedules

- Stay on top of budgeted maintenance costs while planning

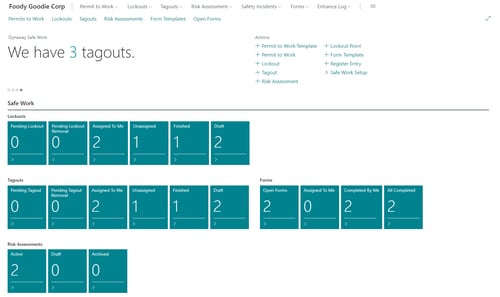

- Ensure compliance using checklists and work permits

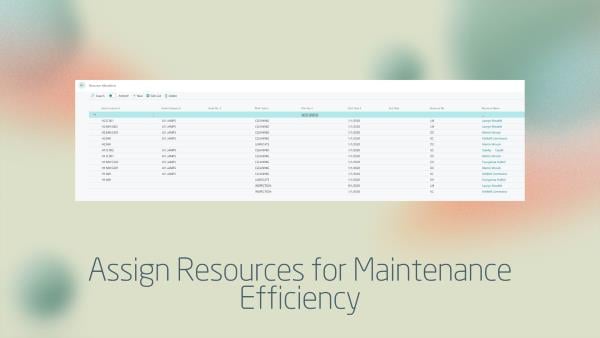

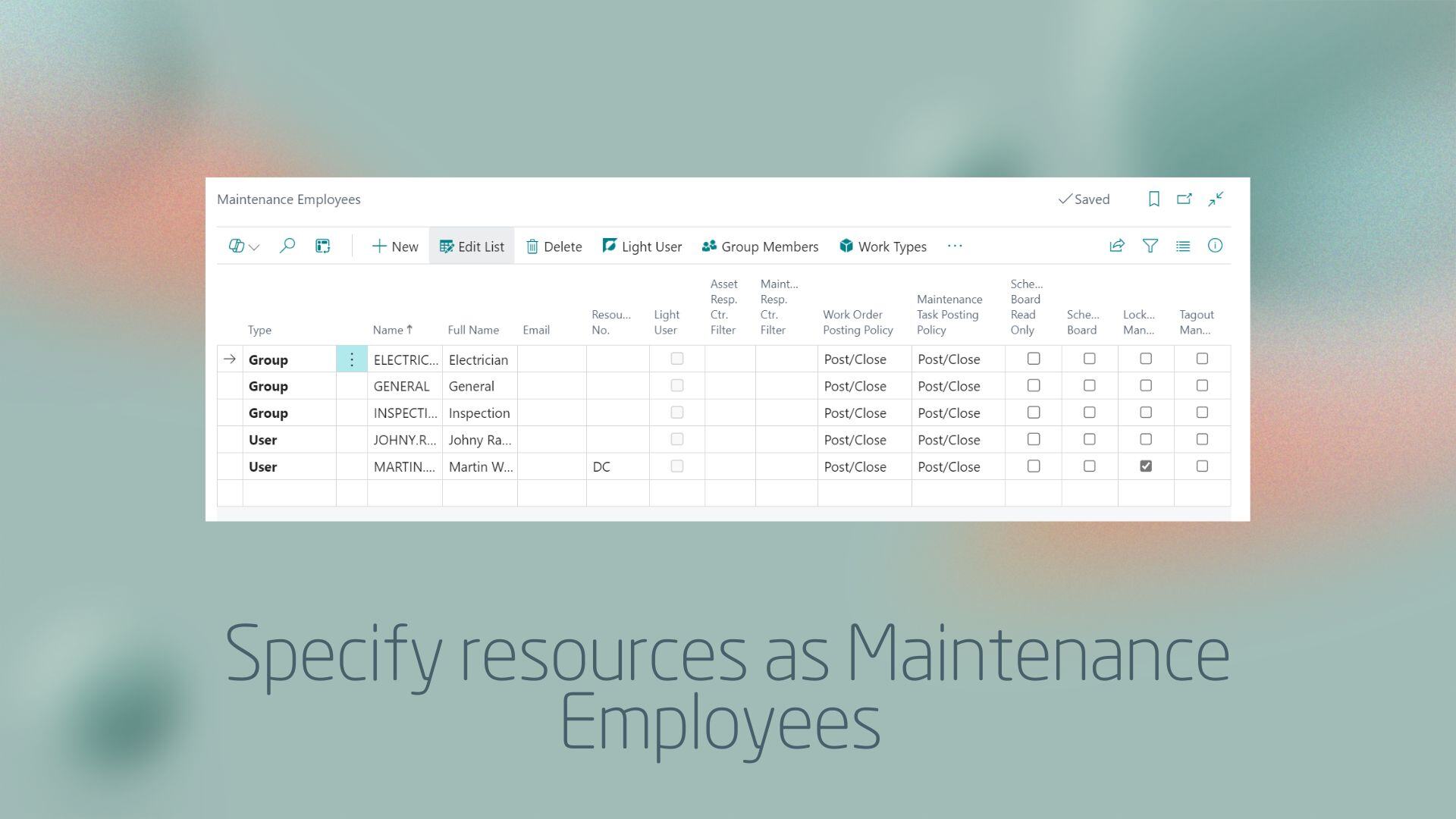

Create and assign corrective Work Orders to structure the execution of maintenance tasks and capture costs of working hours, spare parts, and related expenses. A Work Order can hold all information and documents required to complete the Work Order successfully:

• Include photos and documents

• Create and use your own customized checklists to give instructions

• Track task duration with clock-in/clock-out

• Issue work to contractors by printing or sending work orders

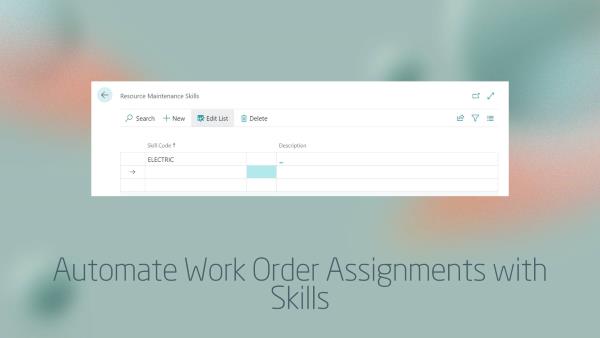

• Assign work by resources’ maintenance skills

• Plan multiple work orders in batches

• Log consumption of spare parts, work hours, and expenses

Create Work Order Plans to automatically trigger pre-defined Work Orders using different frequency types.

Calendar frequency:

Using this frequency will trigger a Work Order based on any time interval.

Counter/Meter frequency:

Using this frequency triggers a Work Order based on an Asset’s Counter/Meter readings reaching a threshold, such as running hours or milage of an Asset. You can add multiple Counters/Meters on the same Work Order Plan. Counter readings can be registered manually or automatically.

Event frequency:

Trigger Work Orders based on asset events. You can set up an event frequency schedule to trigger Work Orders whenever an asset’s location, status, or condition has been changed. You can then limit the values the event should react to. For instance, if you have chosen to trigger a Work Order based on an asset changing location, you can limit it to trigger the Work Order only when the asset reaches its new location.

Measurements frequency:

Measurements is a frequency type that can be used on your Work Order Plans to automatically trigger condition-based Work Orders based on specified parameters meeting thresholds (e.g., humidity, vibration, temperature) based on data from assets’ measurements.

Measurement readings can come from Measurement Devices that consist of multiple measurements set up as one device in the system. They are designed to automate an inflow of data of measurement readings through our built-in API. This allows gathering of data from industrial IoT devices.

Follow-up Work Order frequency:

Using this frequency triggers a Work Order based on the status of another Work Order. If you need to check up on specific maintenance work, you can create a follow-up work order for the future.

Sequence frequency:

Work Order Sequences are used in situations where you have dependency between Work Order Plans. They allow Work Order Plans to be triggered in a specified sequence. I.e., "First clean, then calibrate the machine". This enables you to avoid double work.

The sequence of Work Order Plans can be based on Counters and/or Calendar frequencies.

Group Work Order Plans to make changes to multiple Plans at the same time and keep them synchronized. Grouping Work Order Plans is ideal when you have multiple Assets that need the same type of maintenance but may be at different locations or operated by different technicians.

You can create a maintenance job for multiple assets using Round Plans. They work similarly to Work Order Plans and are ideal to use when you have multiple assets in the same location that all require the same work, for instance a daily cleaning inspection.

Register planned and unplanned downtime on your assets to plan shutdown of a machine or work center that require inspection or maintenance. Register Downtime from an Asset or a Work Order Plan.

Create and add Checklists with detailed instructions to your Assets, Work Orders, Work Order Plans, Work Order Permits, and Asset Transfer Orders to ensure that work can be executed in a compliant and correct manner.

Use Work Orders or Work Order Plans to create an Asset Replacement Order to support the process of replacing an old Asset with a new Asset.

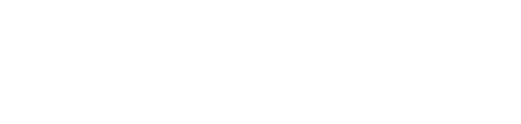

Manage and keep an overview of all requests for maintenance. You can communicate directly on the Maintenance Request with the requestor and subsequently create a Work Order based on the Maintenance Request.

All employees can submit Maintenance Requests to the maintenance team for review without a Dynaway license.

Create Tasks and keep an overview of all tasks that your technicians need to do besides maintenance work. You can plan tasks such as first aid training for technicians or checking sprinklers in an office (not related to your assets) using measurements or counters. You can then plan your maintenance-related work around those tasks.

Tasks work like Work Orders but are dedicated to Resources only.

The vendor integration allows you to set up Contractors as Vendors. In the event when maintenance tasks require specific skills that you do not have in-house, you may need to hire a specialized contractor to perform the work for you. You can create expense registration lines on Work Orders for Contractors' work hours.

You can also print and send Work Orders directly to Contractors.

This feature enables closer alignment between finance teams and maintenance teams to work together to meet budgets.

Maintenance budgets provide a financial overview of planned maintenance costs for the coming year or any other given period. It is also possible to do scenario planning by having multiple maintenance budgets - where each budget targets a scenario.

- Create multiple maintenance budgets for Assets, Asset Locations, Asset Categories, and Work Order Categories

- Copy budgets between periods with defined markup

- Create budgets based on actual data for a defined period

- Import and export budgets from/to Microsoft Excel

- Review budgets with actual consumption for Resources, Items and additional expenses

- Integrates with your own specific Financial Dimensions

Using Warehouse and Inventory Pick allows you to manage and track inventory and warehouse operations related to maintenance tasks, ensuring accurate and streamlined processes.

When setting up locations for spare parts used for maintenance, you can choose to set them up either as Inventory Pick or Warehouse Pick. This means that you will be able to create a pick directly from a Work Order document.

You can set up the relevant people in your maintenance team to get notified outside of Dynaway EAM about events such as a resource getting assigned to an Order or someone making changes to Work Order Plans.

Easily create quotes to let customers approve service costs before work begins. Work Orders and Round Orders can then be generated based on approved quotes. The service price can be set as time & material or a fixed price, ensuring consistency on the invoice. Sales orders and invoices can be created for customers from completed Work Orders or Round Orders, streamlining the process from quotation to billing.

Use Work Order Actions to define tasks that should be done on Work Orders, Work Order Groups, and Work Order Plans. Resources and Items can be specified on each Action and are automatically added to the Work Order when the action has been added.

Manage and track customer contracts in one place

Use Customer Maintenance Contracts to manage and track customer contracts in one place, streamlining contract-based service management.

It automatically calculates contract charges and generates suggested sales documents based on charge periods.

You can create sales documents directly from contracts, efficiently manage work orders, and clearly define which services are covered while keeping any additional costs separate.

Ensure iten availability through reservations

Use Inventory Reservations to ensure item availability Inventory for work orders by reservering stock or expected receipts. It helps you plan work orders efficiently and secure critical items in advance. It is especially useful for hard-to-obtain items, preventing shortages and streamlining planning.

Plan maintenance based on operating time

Maximize operational efficiency with the Asset Calendar, which gives you a clear and customizable view of asset availability. You can link assets directly to work centers and machine centers in Business Central’s Manufacturing module, allowing assets to inherit working hours and schedules automatically. This makes it easier to align maintenance with real operating time, reduce downtime, and improve planning and productivity.

Prioritize assets based on criticality

Easily assess and manage the importance of your assets and items to help you prioritize resources and minimize downtime. Define key criteria and levels to determine how critical an asset is to your operations. Track changes over time through maintenance logs and archive historical data for reference. With flexible configuration options, you can make informed maintenance decisions based on clear and defined criticality levels.