'Change before you have to', Jack Welch once said.

In those five little words are all the implicit risks involved in not changing, not modernizing, and not moving ahead with the game. The day will come when you just have to do it. And by then, your business may be taking its last breaths. Paper-based maintenance and operations management is old news and has been for quite some time. There are, however, many organizations still holding on tightly to ring binders, polypropylene punched pockets, whiteboards, dry markers, clipboards, unsharpened pencils, and yellowing stacks of paper in filing cabinets.

- To be effective, your maintenance decisions must be data-driven.

- Having digital EAM/CMMS enables you to access maintenance and operations data from anywhere.

- Use Kotter’s 8-Step Change Model for implementing a digital EAM/CMMS in your organization.

Why is that?

Resistance to Change

Organizational change is hard. It needs vision, leadership, and a plan. Not only this, but people also have to want to change. They have to want to go from paper, pens, and pencils to digital EAM/CMMS. And for this, the organization and the leadership need a firm, methodological plan.

But before we come to that, why go to a digital solution for EAM/CMMS in the first place?

The Benefits

There's great value in moving from paper to digital EAM / CMMS; here are just a few examples:

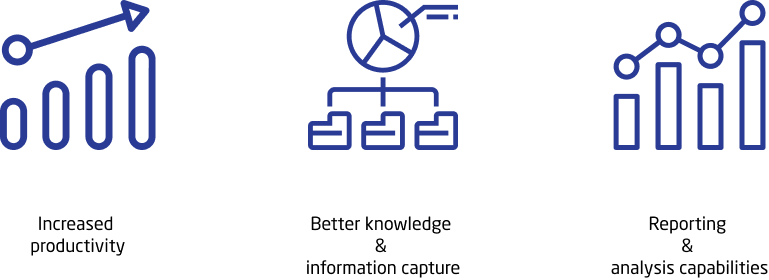

Increased productivity

Cloud-based software allows anyone with a login and Wi-Fi connection to access maintenance and operations data from anywhere. Mobile solutions permit technicians to use tablets and phones at the work site to manage work orders, look at manuals, and check for spares in stores.

Better knowledge and information capture

An EAM can standardize data and processes and store knowledge in the form of maintenance procedures, PM inspections, and asset history. Maintenance performance data converted to information is business intelligence.

Reporting and analysis capabilities

Maintenance decisions must be data-driven to be effective. Everyone requires access to digital dashboards and reporting functions. Technicians and CEOs must be able to see KPIs, data, trends, and performance changes at the touch of a button.

Paper out, digital in.

Now the question is, how can we plan and manage this change?

A Change Framework

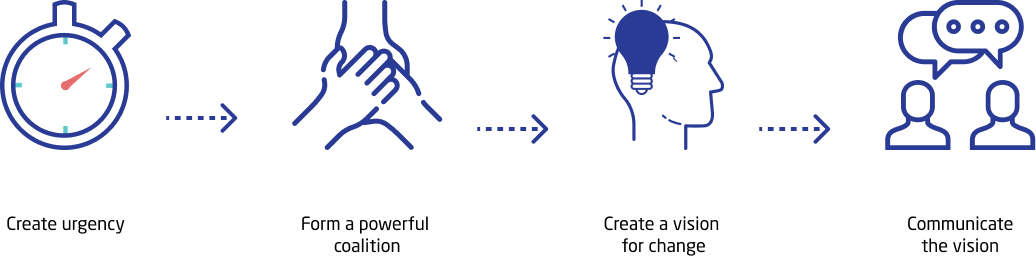

One of the best and most well-known frameworks for change is Kotter's 8 Step Change Model for implementing an organizational change. Here's a rough guide on how to go from paper to a digital EAM or CMMS:

1. Create urgency

Here you'll need a champion or two. And the support of a senior leader. Someone has to start the conversation and shout about the positive opportunities that digital EAM/CMMS will bring. They have to prove it with data and analysis. How much is the paper system costing the company right now in poor maintenance productivity, low asset availability, wasted effort, and lost production?

And when they have that information, tell everyone.

The people need to see it, hear it, and - emotionally - feel it.

2. Form a powerful coalition

So, you've created urgency. But now you need a team and leaders for change. Ask yourself who are the stakeholders in an EAM / CMMS? Who do papers and pencils really affect? Definitely engineering and maintenance management. Look in planning and finance. Look in the stores. Look for leaders on the shop floor in maintenance and operations. Natural leaders and influencers don't always follow the traditional organizational hierarchy.

Get the right people together and build that team.

3. Create a vision for change

This is where the vision, strategy, and delivery plan is finalized.

With the team, create the vision for the new EAM/CMMS. What do you see it delivering? What are the benefits for all? What value will it bring to the organization now and in the years ahead? How will people engage with the EAM/CMMS? What are the inputs/outputs of the system?

Your strategy and delivery plan must consider things like timelines, tasks and activities, communication, project managers, roles and responsibilities, risk analysis, cost-benefit analysis, training, feedback, and many others.

Create a robust and agreed strategy to execute the vision.

4. Communicate the vision

Talk often about the change vision and the benefits of going digital to the people who will use the EAM/CMMS. You have to be open and honest and address peoples' objections, worries and anxieties.

“The secret of change is to focus all of your energy not on fighting the old, but on building the new”. Socrates

One of the best ways to sell and communicate the vision is to address the What's In It For Me (WIIFM?) question. People will change a lot faster when they understand how the new EAM/CMMS will make their lives easier.

Less time looking through cabinets and files. Easier location of spares. Quicker access to asset and failure data. Simpler, quicker audit trails. Automated parts ordering. No need to carry sheets of paper everywhere. Quick access to digital shift reports. The list goes on…

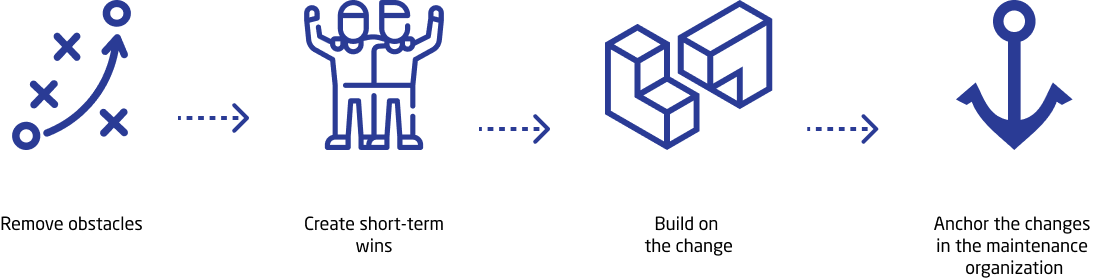

5. Remove obstacles

Inevitably, there will be obstacles during your digital implementation. These may often be people and processes. Some engineers may adore using pen and paper for work orders, some operational processes may be set up to promote the use of filing cabinets and stacks of paper.

People need to be convinced; processes need to be changed.

Identify the resisters and help them see the vision and WIIFM. Aim to swiftly remove process and procedural barriers.

To remove obstacles and roadblocks, use the change leaders whose principal roles are to deliver the change. Look at the structure, job descriptions, and performance and pay systems – they must be consistent with the vision.

Most of all, recognize and reward people who embrace the change.

6. Create short-term wins

These will help the wider audience see that the new EAM/CMMS can deliver the promised benefits and value. It will also help quieten down the naysayers.

One short-term win could be to train a full shift of engineers to use the new EAM/CMMS for all reactive and planned maintenance and compare and communicate the reduction in paper and time wasted. Another idea could be to demonstrate the speed with which tablet-based PM inspections can be signed off and uploaded to the web-hosted software (with photos of asset defects attached). Another could be to demonstrate the ease and speed with which KPIs can be set up to show maintenance management performance.

Look for easy-win mini-projects that can be implemented quickly and that demonstrate the opportunities on offer. And don't forget to reward the people who help you meet the targets.

7. Build on the change

Short-term wins are great but you have to build on them to convince the whole organization that the EAM/CMMS is here to stay. Keep on delivering wins and constantly communicate with all stakeholders on all aspects of the system. Set goals for constant and continuous improvement of the system: is the asset register right? Are all spares, quantities, and costs accurate? Is everyone trained? Is there an agreed process for work management? Are work orders collecting the right failure information? Are KPIs set up adequately?

8. Anchor the changes in the maintenance organization

The change – the new EAM / CMMS – must become a central part of your maintenance organization. Maintenance culture usually determines what gets done, so the values and vision must be displayed by the change leaders and engaged maintenance stakeholders at all times.

Those key stakeholders need to continuously ensure that the new maintenance management digital solution is being used at every opportunity. This will set a strong foundation for the future.

It will then become business as usual.

If you're a maintenance manager or change leader, here's what you can do:

- Talk about the new, digital solution to anyone who'll listen – making sure it's in the general consciousness

- Promote the success stories

- Ensure it is front and center in the training of new staff.

To conclude, change is never easy when many layers of people are involved. You need a plan for meaningful change, and this comes from a model or a framework like Kotter's 8 Steps. Moving from pen and paper to a digital EAM / CMMS will be challenging. You have to sell the idea and the value to people, but more importantly, show it to them in practice.

.png?width=388&height=200&name=Copy%20of%20Blog%20Featured%20Image%20(4).png)