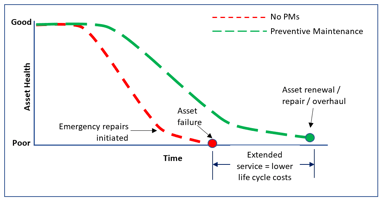

Preventive maintenance is vital for every business. Without proper preventive maintenance, problems arise which can be far more expensive and which often result in downtime and angry (or even lost) customers. Ensuring that preventive maintenance is done involves having a proper maintenance plan which ensures nothing is forgotten. Many companies, however, still rely entirely on corrective maintenance, that is to say they wait for something to break before fixing it.

Also read: Preventive Maintenance Sequences

There is a number of reasons why you should have a proactive maintenance plan.

So, how do you plan maintenance properly so as to make sure everything is done? You need to put together a preventive maintenance plan, which will make sure that everything is done properly:

Audit Critical Assets

If you have not had a proactive maintenance plan in place before, then your first step is to identify which equipment is the most critical. This is how you audit critical assets in Dynaway EAM: Establish what would cost the most money or cause the worst loss in productivity if it failed. These assets are the most important to put on the schedule, especially if you're seeking buy-in from those higher up. Using critical assets allows you to demonstrate the savings quickly. This also lets you 'step up' to the full schedule and allows employees time to adjust. Ask yourself three questions:

- How important is this machine for production?

- Does it require routine maintenance?

- How expensive is it to repair or replace it?

You are looking for machines with solid recommendations for regular maintenance and high repair and replacement costs. Avoid equipment you know will need to be replaced soon anyway.

Put Together the Information You Need

When you put together the plan in Dynaway EAM, you will need to gather some key information which will help you demonstrate the need for it and help you start to establish what needs to be done and when.

You have three good sources for this information:

- Manufacturer recommendations. Manufacturers are able to gather a lot of data about how their equipment functions and when it needs to be cleaned and repaired. Use it. If the equipment is a few years old, check their website, as there might be updated recommendations from the manual that came with it.

- Your own maintenance logs, which should tell you when machines needed to be repaired and what kind of repairs were done.

- Your maintenance technicians, who should have a good sense of how the equipment behaves and when and how it goes wrong. Their expertise is extremely valuable and you should use it.

Use this information to make a list of tasks and their schedule. Make sure that your maintenance staff are clear on what they have to do, which is another good reason to ensure they are involved in the process.

Create the Plan

Once you have the list, you need to put it into a maintenance planning tool. You should use a modern CMMS (Computerized Maintenance Management System) as your tool rather than relying on spreadsheets. Dynaway EAM includes a full featured CMMS as one of its components. Maintenance scheduling software will send alerts to your maintenance staff when they need to work on a machine, so that there is a greatly reduced chance of maintenance being forgotten or blown off. The software will then log when the task is done.

The list for each machine will then become part of the master list of required maintenance, which can easily be expanded as more assets are added to the maintenance plan.

Once you have the plan, go over it with your maintenance staff. Make sure that any staff members who are not trained on these functions get the training they need. It can be worth sending them for training on more complex tasks. For simple tasks, an existing team member should be able to go over it with them. Another advantage of preventive maintenance is that your staff get more practice and more experience working with the equipment.

Track and Fine-Tune

Your initial plan is unlikely to be perfect. There is a high risk of actually scheduling more maintenance than is necessary. Maintenance staff should work with mobile EAM system to log all maintenance and keep track of machine performance. You may find that the manufacturer's recommendation to clean every three days should really be once a week. You should never assume that your maintenance plan is perfect. Bear in mind that in some cases, machines may need some tasks done more often as they age. If the machine operates perfectly, you may be able to get away with less maintenance. If it's still breaking down, then something is missing.

It is still vital to listen to your maintenance technicians, as they know better than anyone how your equipment works not in theory, but in the actual practical situation you are in.

Expand

Ultimately, your preventive maintenance plan should cover all assets you have, although you may not be able to expand that quickly, depending on the size of your company. However, if you try and get it completely right first, you may never actually manage to expand.

For each new piece of equipment you add to Dynaway EAM, you need to go through the same steps of choosing the asset, getting information on the maintenance it needs, and then making the list and adding it to your maintenance scheduling software.

Once you have your preventive maintenance plan in place, you should compare your maintenance costs with prior years so you know exactly how much money it is saving you.

Tracking downtime is also a good idea, both to fine tune the maintenance plan and to demonstrate to shareholders and your superiors how well it is performing. Remember that your plan is never a completed thing, but rather a work in progress that should be constantly monitored and adjusted to ensure it is still where it needs to be.

If you are working up a preventive maintenance plan for your facility, check out our Preventive Maintenance Factsheet, which will tell you what Dynaway EAM can do for you in terms of helping you put together a plan, track your budget, and ensure maintenance requests get to the right person.

Make sure you have went through all the steps!

Continue to read: All you need to know about Preventive Maintenance

-1.png?width=388&height=200&name=Webinar%20MS%20AM%20Mobility%20(2)-1.png)